Charting the growth trajectory

August 24, 2022

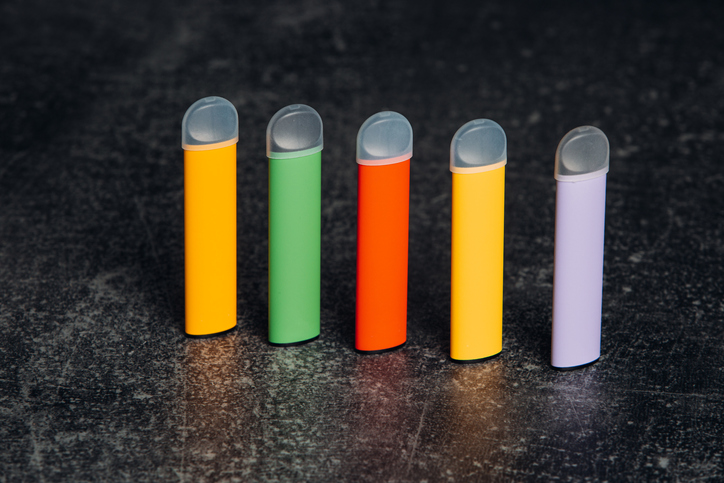

The constant demand, growing health awareness, and the need for safer vaping products have led to lots of innovation in the vape category. From providing varieties of flavour products to fulfilling vapers’ taste preferences to bringing non-heated technologies for turning e-liquid into vapour and water-based vaping products, the vape manufacturers are constantly innovating to boost growth in this sector.

Atomisation to forefront

Atomiser refers to the wick and coil within a vape device. The wick draws in e-liquid from the tank and onto the coil – the element that heats the e-liquid to produce a vapour. To provide safer products, manufacturers are innovating the conventional technology in the vape products.

Pete Lomas, Managing Consultant, Device Development at Broughton said, “A growing trend in the vaping industry is the development of non-heated technologies for turning e-liquid into vapor, thus removing the need for conventional heater coil technology.

“A quick search through recently published patent applications shows the many different approaches engineers are looking at for the ‘atomisation’ of e-liquid, rather than just conventional ‘vaporisation’. Traditional vaporisation heats the e-liquid past its boiling point turning it into a gas, or vapor. Newer technologies involve atomisation, which mechanically acts on the e-liquid to create a fine mist or spray, similar to a vapor cloud but without the need to add heat.”

Lomas notes that a vaping product that does not heat the e-liquid has several advantages. “By not applying heat to the e-liquid the risk of harmful emissions may be reduced. The vapor temperature is lower, so the risk of harm or irritation to the user may also be reduced. In addition, the potential to control vapor particle sizes with new atomization technologies could result in the more efficient delivery of nicotine to the lungs.”

The technologies being used for the atomisation of e-liquid (such as ultrasonics, piezo-ceramic mesh, micro-nozzles, etc) have been around for many years in different industries and applications, such as medical nebulizers. However, the challenge has been to make these technologies commercially viable and small enough to fit within a vaping product, he says.

“Another challenge has been to match the e-liquid properties with the requirements for the new technologies. Typically they require lower viscosity e-liquids than are currently on the market today in order for the atomisation to work effectively. However, in conventional vaping products lower viscosity liquids historically have had greater leakage issues,” he adds.

“Some non-heated products have already been commercialised on a small scale, and it is expected that many more will enter the market in the coming years.”

Ceramic cores turn nano

Recently, Chinese vape brand Zovoo unveiled its new nano-tech ceramic core, named Gene Tree Special Edition with an aim to become a leader in atomisation technology through nano-microcrystalline materials and technological innovation, providing users with a natural and pleasant vaping experience.

Compared with previous ceramic cores, Zovoo Gene Tree Special Edition has “powder-free” ceramic core proprietary patented technology, which the brand described as an industry first. This breaks the bottleneck of sticking and dropping powder in the traditional ceramic core, realising real powder free puff experience and truly enjoying the purity of every puff.

Under 25 times microscope, Gene Tree ceramic core has no surface powder, and meanwhile, the high intensity ceramic formed in 1,300°C temperature guarantees the powder-free effects, protecting users’ health.

Zovoo R&D team has also developed the industry’s first Multilayer Microhole Structure by ceramic materials grading, ensuring strong e-liquid control, while providing users with mute vaping. It solves the pain points that users are most concerned about, such as frying oil, poor stability, low service life, oil leakage and other problems that seriously affect the taste and use experience.

Gene Tree Special Edition also offers the superb substitute mouthfeel, by increasing the overall substitution by 26 per cent and increases the consistency of taste by 60 per cent, when compared with other ceramic coils.

“This is Zovoo newly upgraded nano-microcrystalline ceramic core, Gene Tree Special Edition, gives disposable products a new experience of pure inhalation, mute and non-scalding, smooth and delicate, and super-substitute,” the brand said.

“These new atomisation technologies are more of an engineered solution compared with the conventional heater coil, and as such deliver a much more consistent and repeatable performance,” it added.

Zovoo also released a new disposable product equipped with this technology, DRAGBAR Z700 GT.

Feelm, the flagship atomization tech brand belonging to Smoore, has also introducesd its cutting-edge ceramic coil heating technology to the emerging category of disposable vapes with the new series, Feelm Max.

Almost all the existing disposable vapes are equipped with cotton coil, which produces relatively large aerosol particles, leading to inefficient deposition of inhaled particles in the lungs, hence low nicotine delivery and satisfaction, as well as harshness in throat. Uneven heating of cotton coils could also cause a weak flavor consistency, so that vaping experience will fade gradually, the brand noted.

Feelm claimed the new series will herald a change in the disposable vape category much similar to what internal combustion engine represented to airplanes, automobiles, ships, submarines, and trains.

“It aims to provide the next generation of disposable vapes with a stronger, more reliable and efficient atomization ‘engine’. Just like internal combustion engine, which features high thermal efficiency, light weight, compact size and maneuverability, marking the coming of the second industrial revolution; Feelm Max is expected to lead another ceramic coil revolution in the global vaping industry,” the brand said.

The vaping solution has largely improved e-liquid utilisation by virtue of a cotton-free structure and microporous ceramic coil. Therefore, its puff number is increased by 25 per cent with the same e-liquid volume, compared with traditional cotton coil disposable vapes.

Besides, it can provide an unprecedented silky-smooth vaping experience, thanks to the ceramic coil, which generates smaller vaporized aerosol particles, thereby minimizing residue in throat. In contrast to cotton coil disposable vapes, the smoothness is improved also by 30 per cent. This innovation also boasts extraordinary flavor consistency of over 95 per cent, since ceramic coil can guarantee constant vapor production, so as to bring the same strong and great taste till the last puff.

Tackling addition

Smoore has also launched a real-time monitoring research project on nicotine addiction in partnership with the Shenzhen Institute of Advanced Technology (SIAT), exploring how best to minimise the nicotine strength in vaping products and to bring it to below the levels which cause addiction.

Researchers working on the project will monitor the atomisation of e-liquids to better understand the delivery, absorption, and metabolism of nicotine in the human body. The research will also provide a better understanding of nicotine absorption through different organs to reveal sensory satisfaction experienced by vaping.

“The atomisation process between an e-cigarette and a combustible cigarette is very different, hence the physical and chemical properties derived from atomization and tobacco combustion also varies distinctively,” Dr XiongYuming, Deputy Dean of Smoore Shenzhen Fundamental Research Institute, said.

“Focusing on the underlying mechanism of atomisation and tobacco combustion, our research aims to explore nicotine delivery and absorption, so as to reduce the health impacts of these products.”

With this project Smoore aims to provide products that don’t result in nicotine dependence by reducing the nicotine levels to as close to zero as possible, without scarifying the satisfaction level.

Water-based vapes

Another innovation the sector has recently witnessed is the introduction of water-based vaping products, with UK-based Aquios Labs becoming the first to introduce an entirely new product category to the industry.

The first generation of its technology, dubbed ‘AQ30’, supports up to 30 per cent water content, using a combination of specially formulated e-liquid and hardware design. Most traditional vaping devices and e-liquids contain no water at all, and in those that do, the water content is restricted to 3 per cent or less, the firm noted.

Aquios said they are already developing the capability to support even higher levels of water content.

Positioning itself as a technology company, rather than a consumer-facing brand, Aquios Labs hopes to integrate water-based vaping into existing product portfolios.

Water-based vapes perform differently from their traditional counterparts, the company claims. The water content reduces dehydration and irritation, helps to deliver nicotine more efficiently and produces a more natural flavour. In addition, the operating temperature of water-based vaping is much lower than traditional vaping, which greatly enhances the chemical stability of the vaping process.

Aquios Labs founder Jack Sanders said at the time of the announcement: “We founded Aquios Labs because there’s still a long way to go in terms of improving the vaping experience. We believe that water-based vaping is the new frontier of nicotine delivery and AQ30 is already demonstrating this by drastically reducing the dehydrating effects of vapour while delivering clean flavours. We welcome new and existing vape brands to consider how this technology can be adopted as part of a growing product offering.”

At the UK Vaper Expo, which took place on 27-29 May at the NEC Birmingham, Aquios Labs launched Aquios Bar in partnership with vaping major Innokin, aiming to disrupt the disposable vaping space with water-based technology and a user-recyclable design.

The device is made from less carbon intensive materials and can be disassembled after use, so individual components can be recycled.

In May, Innokin Technology also announced the launch of Lota, a new sub-brand for water-based vaping devices. Lota combines Innokin’s innovation expertise with Aquios Labs.

“Innokin has always believed in embracing new technology. When first introduced to Aquios Labs, our product development team was impressed with the unique advantages of water-based vaping,” George Xia, Innokin Technology co-founder, said.

“Through this exciting partnership, Innokin is proud to launch the Lota brand, offering high performance water-based vaping in our continued quest of tobacco harm reduction across the globe.”

Lota has been launched with a portfolio of three water-based devices, each with their own position for specific global markets and consumer needs: the Lota Enviro, F600, and Prefilled Pod Kit.

The Lota Enviro is a disposable device with a clear mission to reduce the carbon footprint of typical disposable vapes. Enviro achieves this with a unique paper shell design using recyclable materials and user-recyclable components. After the Enviro has been fully depleted, the device can be disassembled by the end user, and every component aside from the e-liquid reservoir can be fully recycled.

The Lota F600 is Lota’s flagship disposable vaporiser, targeted for European markets. Offering stylish, comfortable soft-touch surfaces and lightweight simplicity, it represents the ideal entry to vaping for transitioning smokers. The F600 features a 600-puff lifespan and delivers constant 3.6V output, which means consistent performance from the first puff to the last.

The Lota Prefilled Pod Kit integrates Aquios water-based vaping technology into a closed pod system with a rechargeable battery. Each 2ml pod is designed to last for 600 puffs and the battery provides constant 3.6V output for a consistent vaping experience throughout each charge cycle.